Unveiling Core Factory Processes: An Analysis of Coating, Printing, and Laminating Technologies for Custom Self-Adhesive Wallpaper

For a professional manufacturer like Shanghai MIRO Import & Export Co., Ltd., the appeal of custom self-adhesive wallpaper lies not only in its exquisite patterns but also in the precise and complex production processes behind it. Every high-quality roll of self-adhesive wallpaper is the result of the perfect synergy of three core technologies—coating, printing, and laminating—within a modern factory. Leveraging its strong production capabilities, MIRO transforms this craftsmanship into stable, eco-friendly, and highly customizable products.

1. Precision Coating: The Art and Science of the Adhesive Layer

Coating is the foundation of self-adhesive wallpaper manufacturing, directly determining the wallpaper's adhesion, removability, and environmental friendliness.

Technical Core: The three advanced coating production lines and two backglue coating machines in MIRO's Anhui plant are dedicated to this stage. This equipment can apply specially formulated pressure-sensitive adhesive onto the backing material (such as non-woven fabric, PVC, or pure paper) with extremely high precision and uniformity.

Process Difference:

- Traditional Paste-the-Wall Wallpaper: Requires users to apply adhesive themselves, a cumbersome process.

- MIRO Self-Adhesive Wallpaper: Utilizes advanced pre-coated pressure-sensitive adhesive technology. The adhesive layer is pre-applied and dried at the factory. Users simply peel off the release paper (protective film) and apply directly, greatly simplifying the installation process.

Environmental Commitment: As a company focused on eco-friendly decorative materials, MIRO's choice of adhesive is crucial. The adhesives used are typically low-VOC (Volatile Organic Compounds) or water-based acrylic, ensuring the product is odor-free, safe, and environmentally friendly, aligning with its "eco-friendly sustainable" brand philosophy.

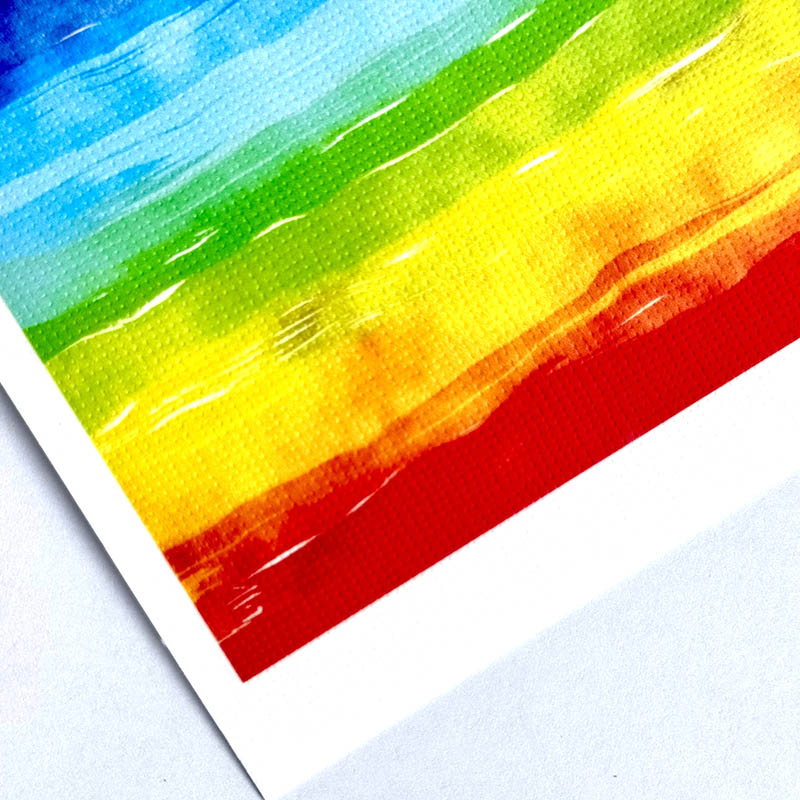

2. High-Precision Printing: Giving Soul to the Wall

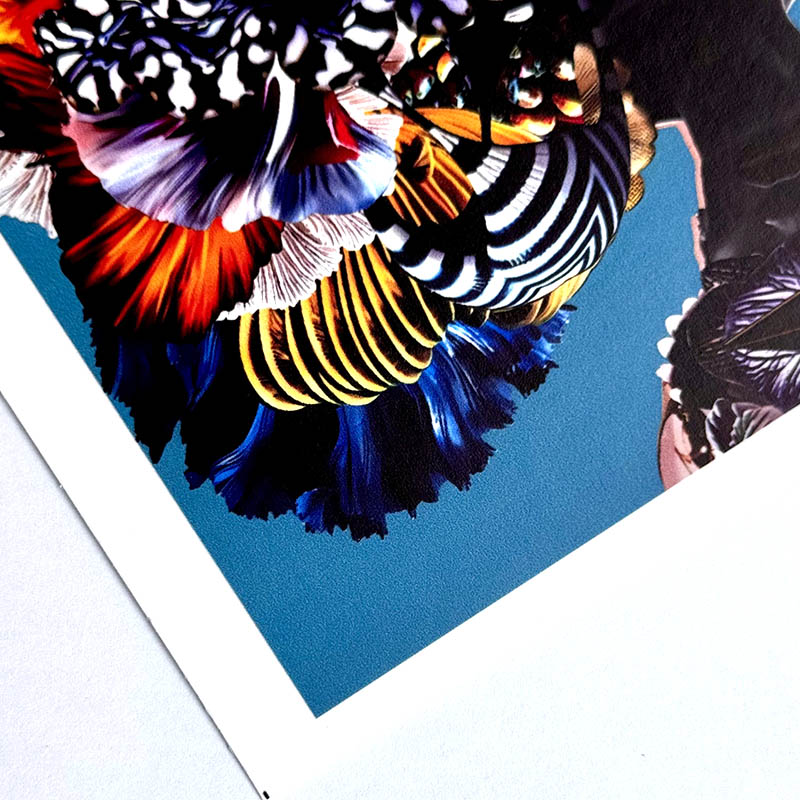

The printing process transforms design blueprints into reality, determining the pattern, color, and overall aesthetics of the wallpaper.

Technical Core: MIRO utilizes advanced gravure printing and likely digital printing technologies to meet different customization needs.

- Gravure Printing: Suitable for high-volume production of repetitive patterns. Its advantages are high color saturation, excellent reproduction, strong abrasion resistance, and high production efficiency, making it ideal for the mass production of standard designs.

- Digital Printing: This is the key to achieving high-level customization. It requires no printing plates and can output digital artwork directly onto the wallpaper, perfectly enabling small-batch production, multiple patterns, and complex gradient colors, meeting the modern consumer's demand for unique designs.

Color Management: Professional colorists and color management systems in the factory ensure that the color of every production batch closely matches the design proof, guaranteeing the accuracy of the custom effect.

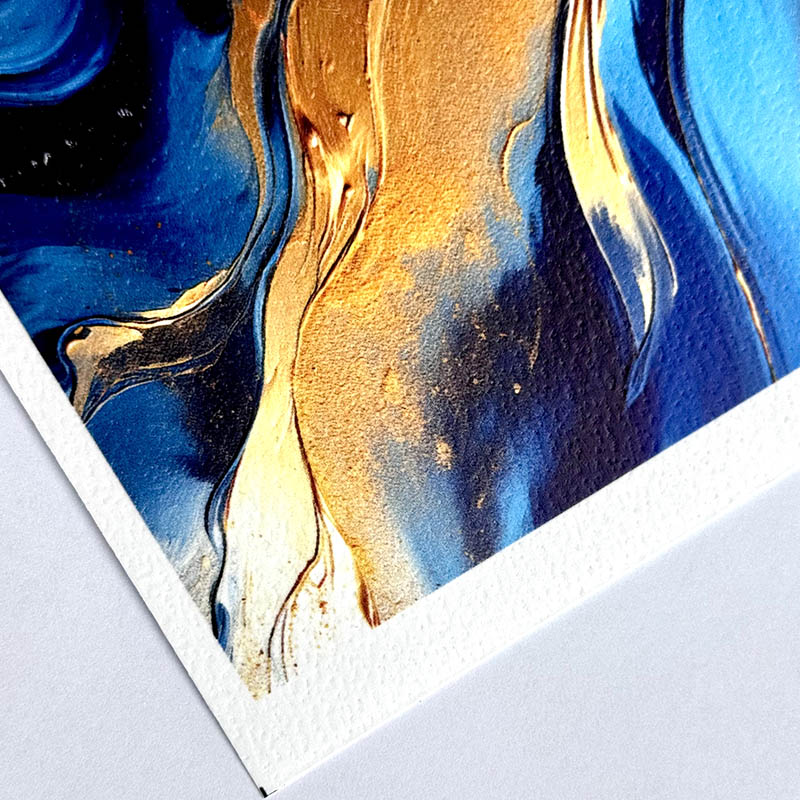

3. High-Performance Laminating & Embossing: The Layer of Texture and Protection

Laminating and embossing processes add the final protective layer and three-dimensional texture to the wallpaper, enhancing the product's grade and durability.

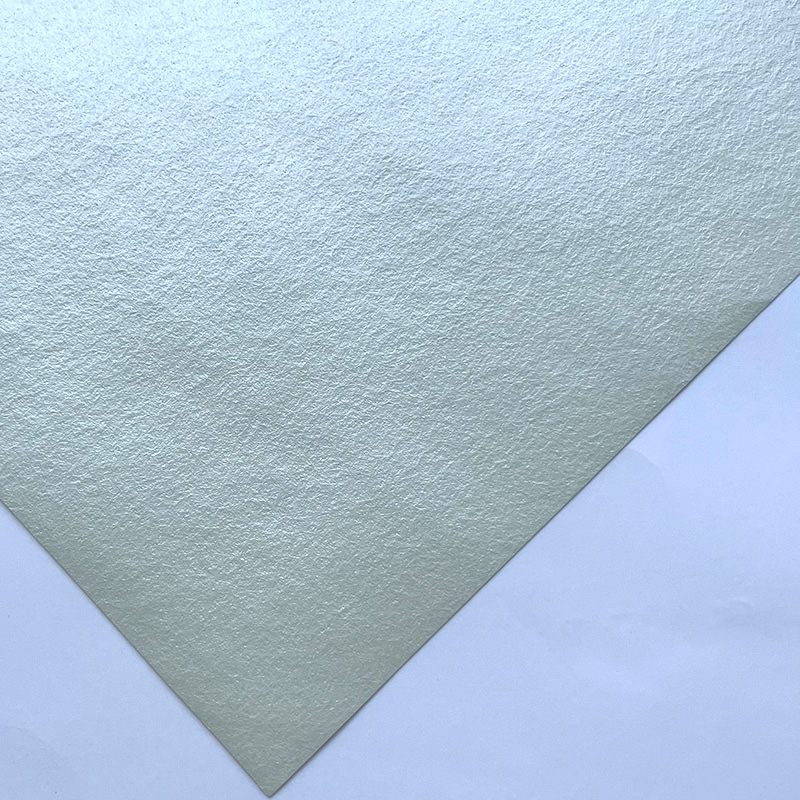

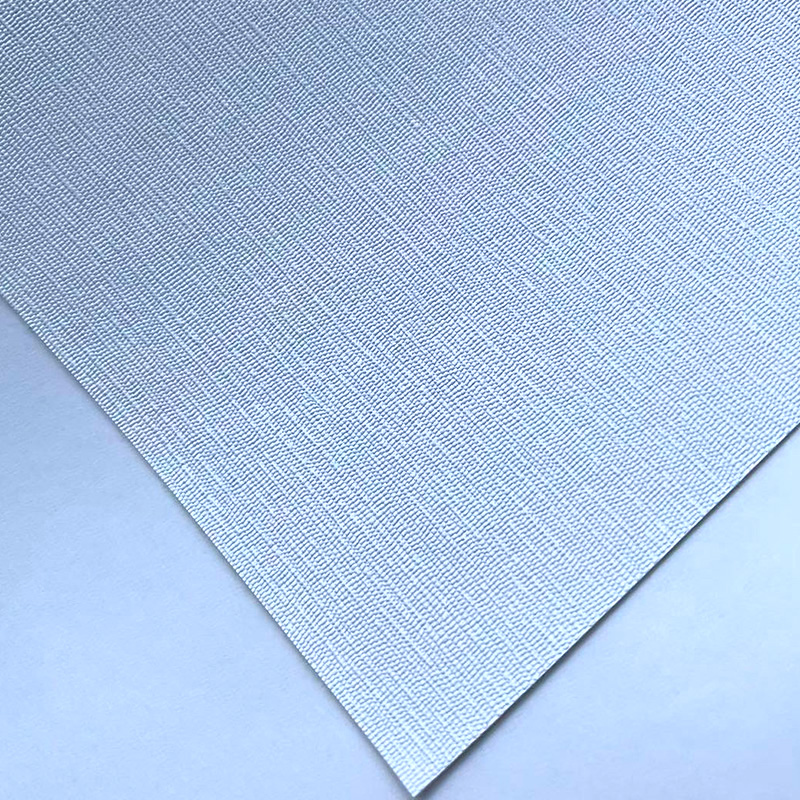

Surface Laminating: A transparent PVC or other eco-friendly coating is applied over the printed pattern. This film effectively resists stains, is scrubbable, and moisture-resistant, extending the wallpaper's lifespan, making it particularly suitable for environments prone to stains and moisture like kitchens and bathrooms.

Embossing Process: The embossing equipment in MIRO's factory can impress various three-dimensional textures onto the wallpaper surface, such as linen, silk, or stone patterns. This combination of touch and vision greatly enhances the product's texture and decorative effect, making the wall more vivid and realistic.

Quality Control: The scuttling inspection equipment acts as the "quality inspector" in the final stage. It automatically detects and marks defects in the roll material (such as color differences, uneven coating, or printing flaws), ensuring every roll delivered to the customer is flawless.

Conclusion

Through its 15,000-square-meter modern production base and a range of professional equipment, Shanghai MIRO Import & Export Co., Ltd. integrates the three technological modules of coating, printing, and laminating into an efficient and reliable production system. This demonstrates not only the strong hardware capabilities of the manufacturer but also its soft power in transforming customer customization needs into high-quality, eco-friendly end products. From the environmental adhesion of the coating, to the accurate presentation of patterns, to the durable feel of the surface, every step embodies the power of technology and a commitment to quality, ultimately resulting in rolls of self-adhesive wallpaper that are not just decorations, but a combination of technology and art.

Beyond Adhesion: How High-Quality Self-Adhesive Wallpaper Wins the Global Market Through Eco-Certifications

In the highly competitive global building materials market, being a professional custom self-adhesive wallpaper manufacturer is not just about offering aesthetically pleasing and convenient products. International buyers and partners are increasingly focusing on the environmental certifications, safety standards, and corporate social responsibility behind the products. For a company like Shanghai MIRO Import & Export Co., Ltd., with over 20 years of history, the various international certifications obtained by its Anhui production base have become both a passport for its products to the global market and a core competitive advantage.

1. Why are Eco-Certifications Crucial for Self-Adhesive Wallpaper?

The environmental concerns of traditional wallpaper primarily stem from volatile organic compounds (VOCs) that may be present in inks, coatings, and adhesives. These substances can be slowly released over time, affecting indoor air quality and occupant health.

Since self-adhesive wallpaper is a pre-coated product applied directly to indoor walls by the end-user, the environmental safety of its adhesive becomes a primary consideration. MIRO's positioning as China custom eco-friendly sustainable wallpaper manufacturers directly addresses this global market demand. Its products adhere to strict environmental standards from the raw material stage, ensuring safety and peace of mind from the factory to the customer's home.

2. Decoding the Key Certifications Behind MIRO's Factory

A modern factory covering 15,000 square meters is itself a testament to quality, and the certifications it holds are the authoritative endorsement of its commitment. Here are the key certifications MIRO and its products likely possess and their significance:

1. ISO 9001 Quality Management System Certification

Significance: This certifies that MIRO has established an internationally standardized quality management system for its entire production process from R&D, procurement, coating, printing, packaging to after-sales service. It ensures product stability and reliability, meaning orders placed today will be consistent in quality with those placed three months later. This is the foundation of being qualified Manufacturers.

2. SGS, CE, and Other Internationally Recognized Environmental Test Reports

Significance: SGS is an internationally recognized third-party inspection, testing, and certification organization. MIRO's products are typically tested by SGS to prove compliance with stringent safety standards such as REACH (EU regulation on chemicals), low VOC emissions, and heavy metal content. These reports directly assure consumers of the product's health and safety and are key to entering high-end markets like Europe and America.

3. Fire Rating Certification (e.g., EU EN13501-1, US UL Standards)

Significance: As a building interior material, the fire performance of wallpaper is a mandatory safety requirement. MIRO's wallpaper products likely achieve different fire ratings (such as B1, C) according to the regulations of different markets. This demonstrates the manufacturer's high sense of responsibility for user safety and is a necessary condition for entering project engineering, hotels, commercial spaces, and other fields.

4. FSC (Forest Stewardship Council) Certification (if using paper-based substrates)

Significance: If MIRO's product line includes wallpaper made from pure paper or non-woven substrates, FSC certification means the wood fiber used comes from sustainably managed forests. This strongly echoes its eco-friendly sustainable brand philosophy and is highly favored by environmentally conscious consumers and brands.

3. How Certifications Add Value to Customization?

Holding these certifications means that MIRO's custom service is not just about personalizing patterns and sizes, but also about the quality assurance behind deep customization.

When a European designer or an American retailer places a custom order with MIRO, they do not need to worry about whether the product meets environmental and safety standards. Because these certifications are integrated into the production DNA of MIRO. Regardless of the order size, all products output follow the same set of stringent international standards. This reduces procurement risk for buyers, builds solid trust, and makes customization smoother and more reliable.

Conclusion

For Shanghai MIRO Import & Export Co., Ltd., the advanced equipment in its Anhui factory is the hard power of production, while the series of international certifications it has obtained constitute the soft power of its brand and a foundation of trust. In global competition, these certifications silently yet powerfully declare to the world: this is a mature manufacturer capable of perfectly integrating personalized customization, large-scale production, and environmental health responsibility. This not only wins orders but also gains market respect and long-term partnerships.

中文简体

中文简体 English

English русский

русский Español

Español عربى

عربى