What Makes Custom PVC with Non-woven Wallcovering Base Manufacturers, Factory So Critical in Modern Wallcovering Solutions?

Introduction – Why Focus on This Intersection?

In the evolving landscape of interior finishes, the demand for sophisticated, high-performance wallcoverings continues to grow. Among the diverse substrates and facing layers, a compelling combination has emerged: Custom PVC with non-woven wallcovering base. This hybrid offers a powerful blend of robustness, dimensional stability, ease of customization, and application convenience. Understanding what makes manufacturers and factories of this composite so essential to design, construction, and renovation can help specifiers, architects, and end-users make informed decisions.

In this article, we explore the science behind PVC-coated non-woven bases, the manufacturing considerations in factories producing such products, quality control protocols, sustainability angles, and application-focused benefits. This deep dive is designed to bring clarity, technical insight, and strategic understanding to the topic—crucial for SEO value and reader engagement.

The Science of PVC-Coated Non-Woven Base

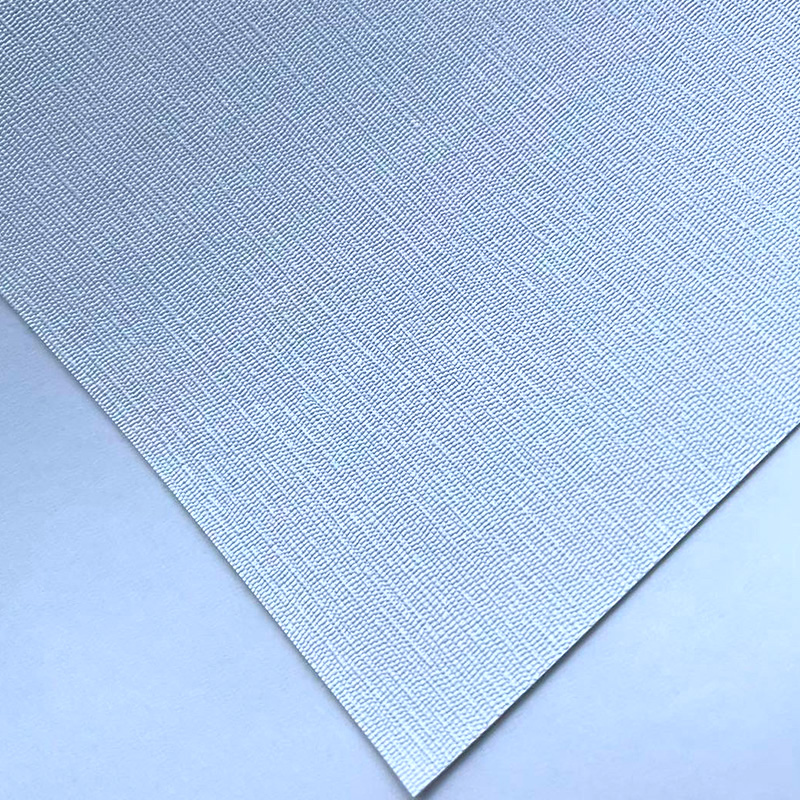

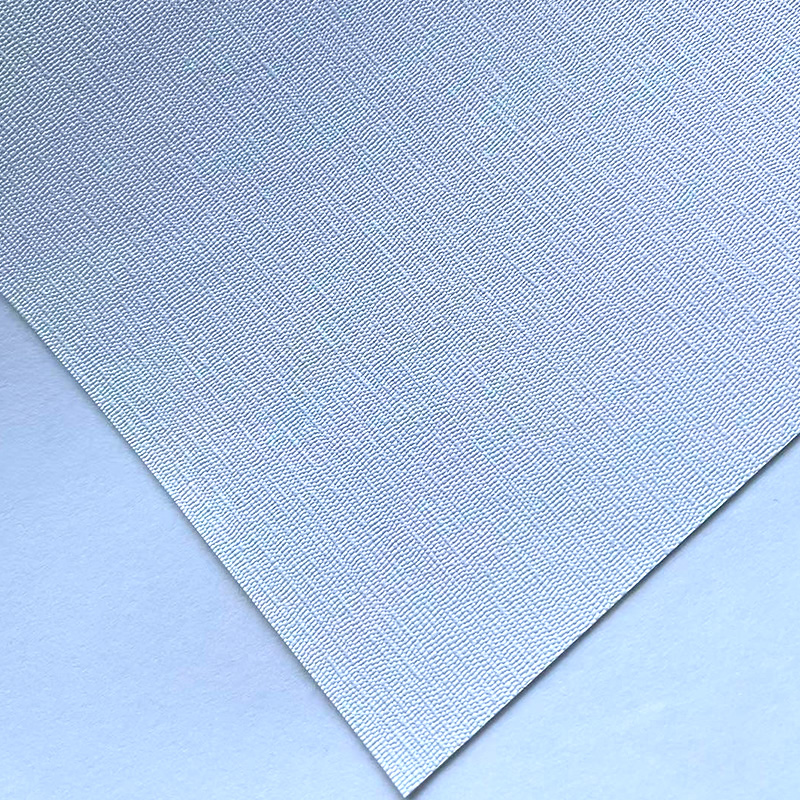

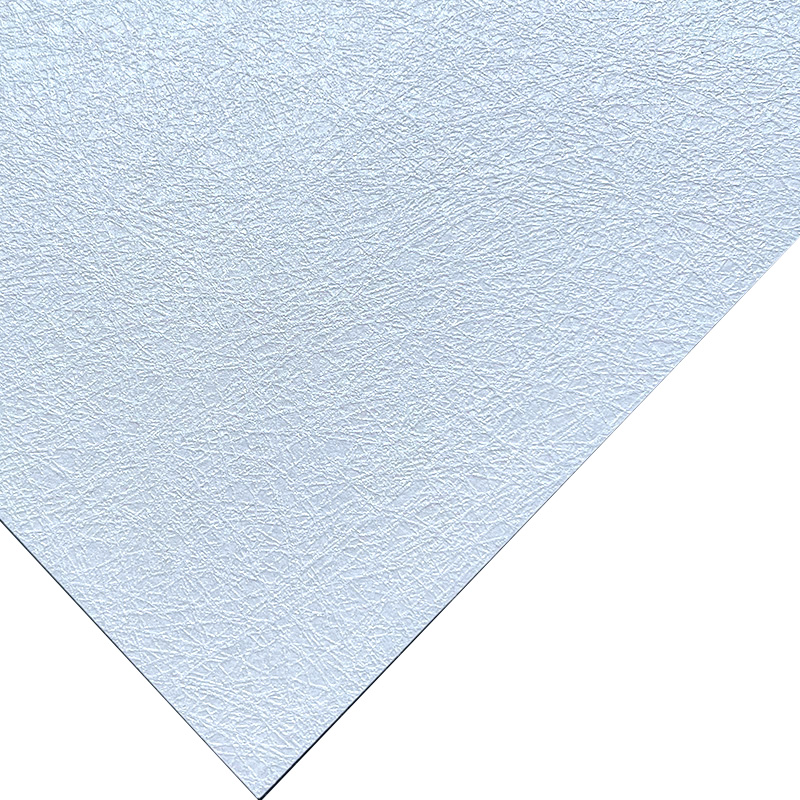

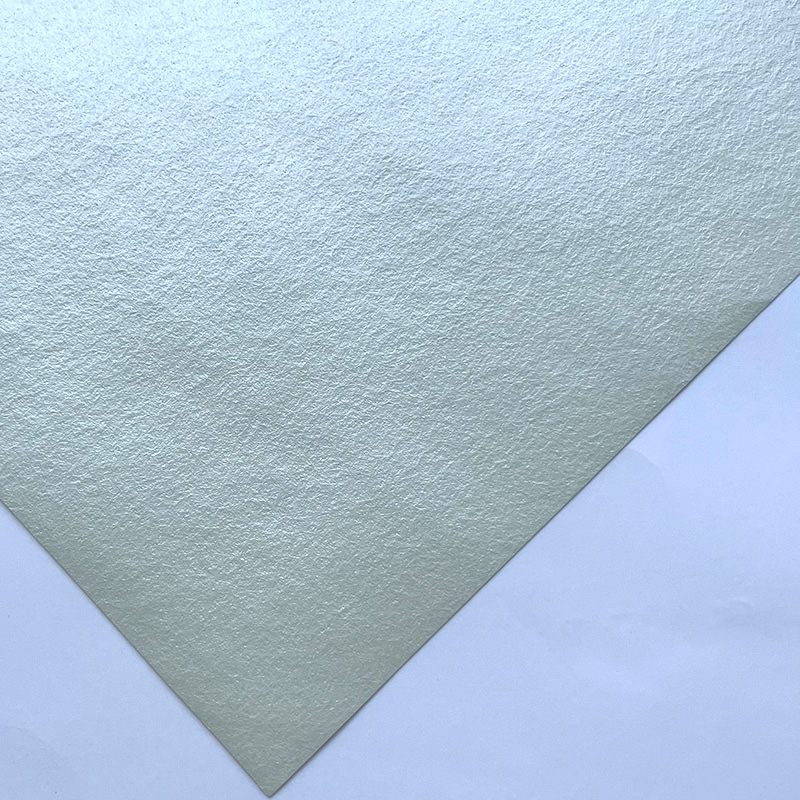

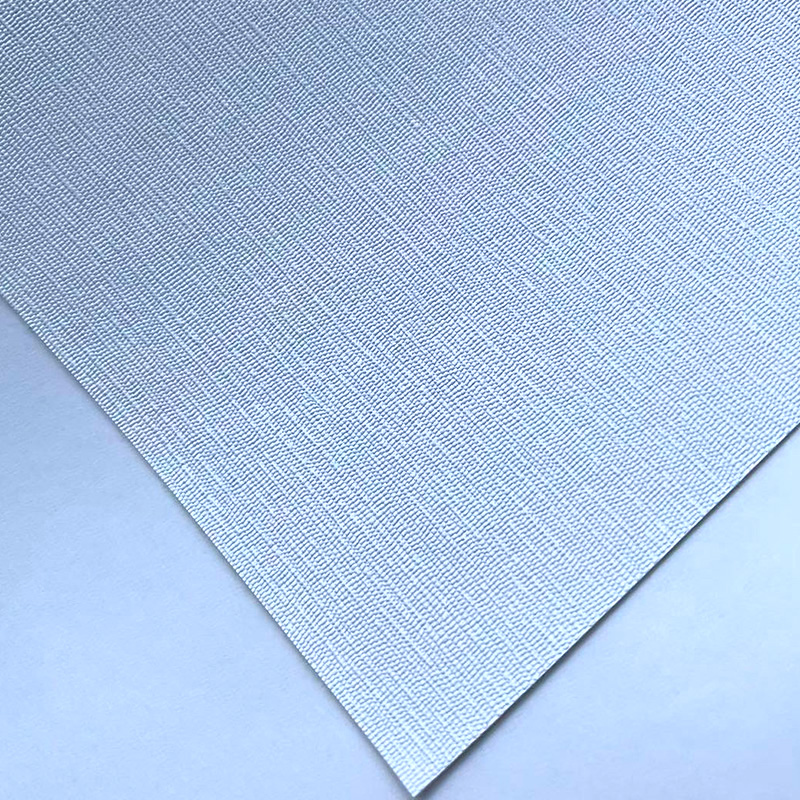

A non-woven wallcovering base typically consists of a fibrous mat—often polyester, cellulose, or blends—bonded together without weaving. The result is a structure that combines tensile strength, tear resistance, and flexibility. Non-woven bases provide an excellent grip for coatings and adhesives, dimensional stability during humid cycles, and ease in cutting and seaming.

When a PVC layer is custom-formulated and applied to the non-woven substrate, it imparts additional properties:

- Water resistance and cleanability: PVC is inherently moisture-impermeable and can be formulated to resist staining and abrasion.

- Surface texture and visual versatility: Through embossing, calendaring, or printing, PVC can replicate textures from leather to linen, or incorporate high-resolution images.

- Fire-performance tailoring: PVC formulations can be adjusted to meet fire codes, including self-extinguishing grades or ASTM/A2-s1, d0 equivalents, depending on region.

- Dimensional stability: The laminate structure resists expansion or contraction driven by temperature or humidity changes.

Therefore, the synergy of custom PVC with non-woven wallcovering base creates a product that meets both aesthetic and functional demands.

Role of Manufacturers and Factories

What do manufacturers factories must master to produce high-quality custom PVC/non-woven composites?

-

Material selection and formulation expertise

Factory technicians choose non-woven fibers with specific weight, basis weight (g/m²), and binder systems to match performance targets (e.g., tear strength, elongation). PVC formulations must interface seamlessly, demanding knowledge of plasticizers, stabilizers, pigments, and UV inhibitors.

-

Lamination and coating precision

Uniform application of the PVC film or liquid coating over a moving web requires calibrated gravure or knife-over-roll coating equipment. Temperature, viscosity, line speed, curing temperatures—all must be controlled to avoid defects like pinholes, delamination, or uneven thickness.

-

Sustainability and compliance

Factories face regulations both for the non-woven base (e.g., recycled content, VOC emissions) and for PVC (e.g., phthalate-free, low-VOC, REACH compliance). Manufacturers implement closed-loop systems, solvent recovery, and record testing data to ensure compliance.

-

Quality control and testing

Robust QC protocols include:

- Tensile and tear testing (ASTM D-1004, ISO 34)

- Dimensional stability after humidity/heat cycling

- Fire-performance testing

- Adhesion testing between PVC and base

- Surface abrasion/resistance to soiling

-

Customization workflow

Tailored color matching, surface embossing, pattern repeat control, and roll-to-roll reproducibility demand meticulous workflow—from digital proofing to pilot runs to full production.

Advantages for Architects and End-Users

For design professionals and specification-minded stakeholders, custom PVC with non-woven base offers:

- Ease of installation: Non-woven bases are stable, shrink-resistant, and often paste-the-wall compatible—making large-format installation faster.

- Long-term performance: Water resistance and robust coating prolong life, reducing maintenance and replacement cycles.

- Design flexibility: Because PVC can be pigmented, printed, textured, or metallized, the aesthetic scope is broad.

- Regulatory coverage: Fire ratings and green certifications can be pre-qualified at manufacturing.

These factors increase adoption in hospitality, healthcare, corporate interiors, and high-traffic residential settings.

Manufacturing Considerations in Scaling and Innovation

Scale-up from pilot to full factory-scale manufacturing introduces new technical challenges:

- Consistency over long runs: Maintaining embossed texture and PVC bond over thousands of linear meters requires automated in-line monitoring (e.g., thickness gauge, adhesion sensor, vision inspection).

- Waste minimization: Edge trims, startup sheets, and off-cuts must be recycled or reused. Advanced factories invest in rewind/rewrap systems, trimmed edge reclamation, or pigmented rework.

- Energy efficiency: Drying ovens and curing systems are energy-intensive. Heat recovery, infrared assistance, and solar-assisted pre-heat systems lower carbon footprint and reduce cost.

- R&D for emerging properties: Development of antimicrobial PVC coatings, caustic-clean-resistant versions, or sound-absorbing embossed patterns reflect factory innovation pipelines.

Featuring Shanghai MIRO Import and Export Co., Ltd. in Context

While discussing the broader Custom PVC with Non-woven Wallcovering Base Manufacturers, Factory ecosystem, it’s notable that some enterprises, such as Shanghai MIRO Import and Export Co., Ltd., participate in the exchange of technical know-how or sample logistics. For example, when collaborating with technical labs or supplying trial runs of composite rolls to designers, a company like Shanghai MIRO offers logistical facilitation that smooths communication between overseas specifiers and domestic manufacturing-site resources—without overshadowing the scientific and manufacturing detail being presented.

Outlook: Future Trends in the Composite Wallcovering Segment

-

Bio-based and recycled components

Integration of recycled polyester fibers in non-woven base and bio-PVC alternatives (e.g., citrate plasticizers, bio-sourced materials) reduce carbon footprint.

-

Smart or functional coatings

Incorporation of UV-blocked coatings, antimicrobial additives, or conductive traces for back-lighting transforms wallcoverings into interactive or protective surfaces.

-

Digital print synergy

Digital print directly onto PVC-coated non-woven media opens opportunities for low-volume, high-custom patterning with no screen-plate costs.

-

Adaptive acoustic properties

Through back-layer engineering—like adding micro-fibrous foam layers beneath the PVC—the total composite can deliver enhanced sound absorption for open-plan offices or lobbies.

Conclusion – Why the Manufacturing Core Matters

In sum, the Custom PVC with Non-woven Wallcovering Base Manufacturers, Factory ability to deliver technically sound, environmentally compliant, visually compelling, and install-friendly wallcoverings depends on a rigorous combination of materials science, process control, sustainability compliance, and custom capacity. Designers, specifiers, and integrators benefit from these manufacturers’ capability to produce composites that meet exacting project requirements, while logistics partners (such as Shanghai MIRO Import and Export Co., Ltd.) can facilitate seamless global collaboration.

By focusing on the scientific mechanics, factory realities, application advantages, and future directions, this article provides both SEO value and reader utility—ideal for drawing interest from Google’s crawling and ranking algorithms.

中文简体

中文简体 English

English русский

русский Español

Español عربى

عربى