How Does Vinyl Wallcovering Shape the Modern Interior Decoration Industry?

Introduction

Vinyl wallcovering has become one of the most significant materials in modern interior decoration, offering a balance between functionality, durability, and design flexibility. It plays an essential role in both residential and commercial environments, where walls are expected not only to be visually appealing but also resistant to wear, moisture, and staining.

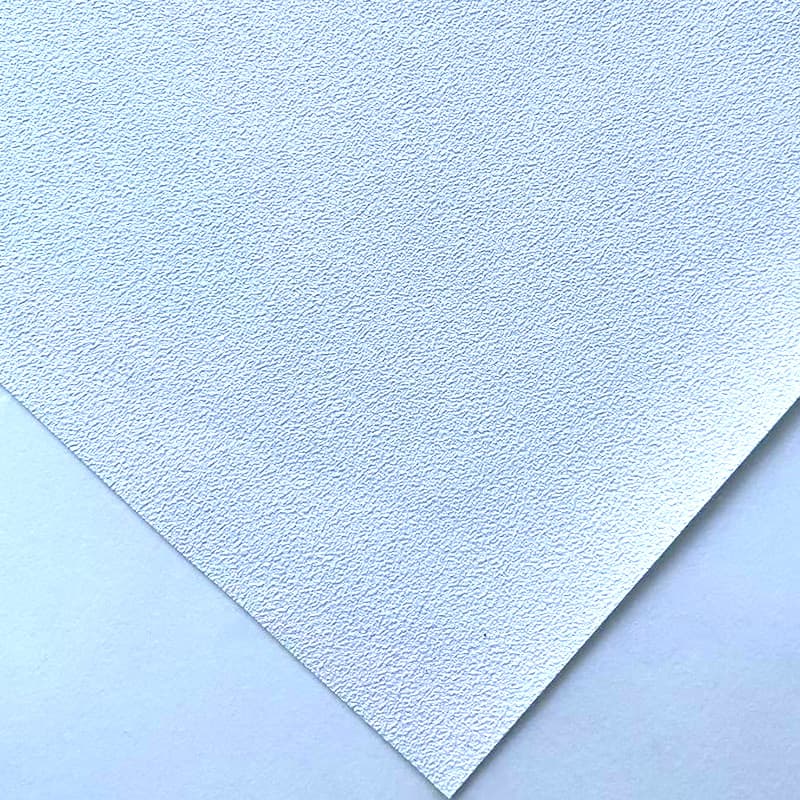

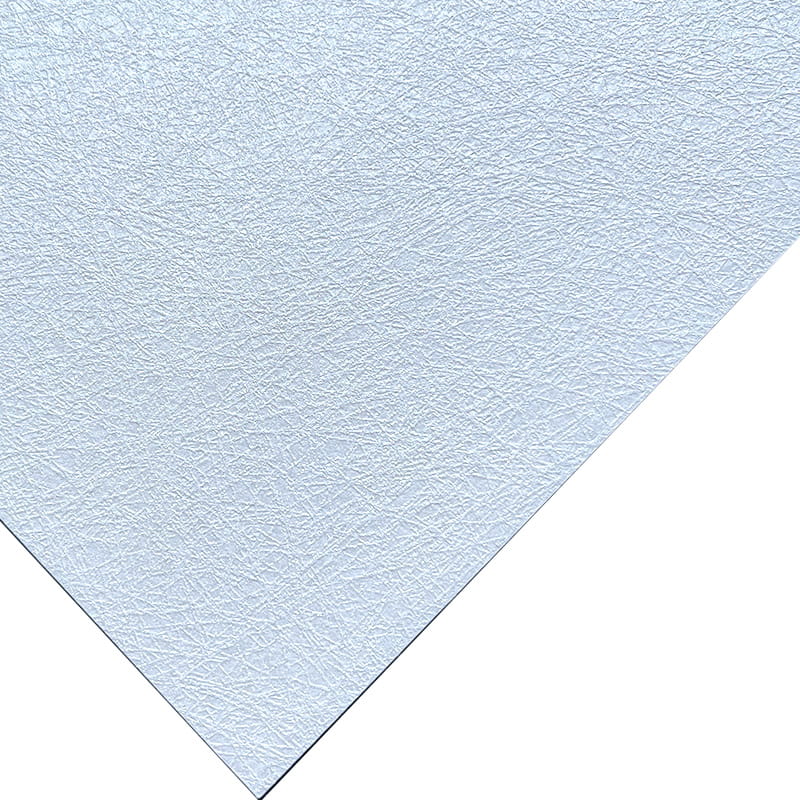

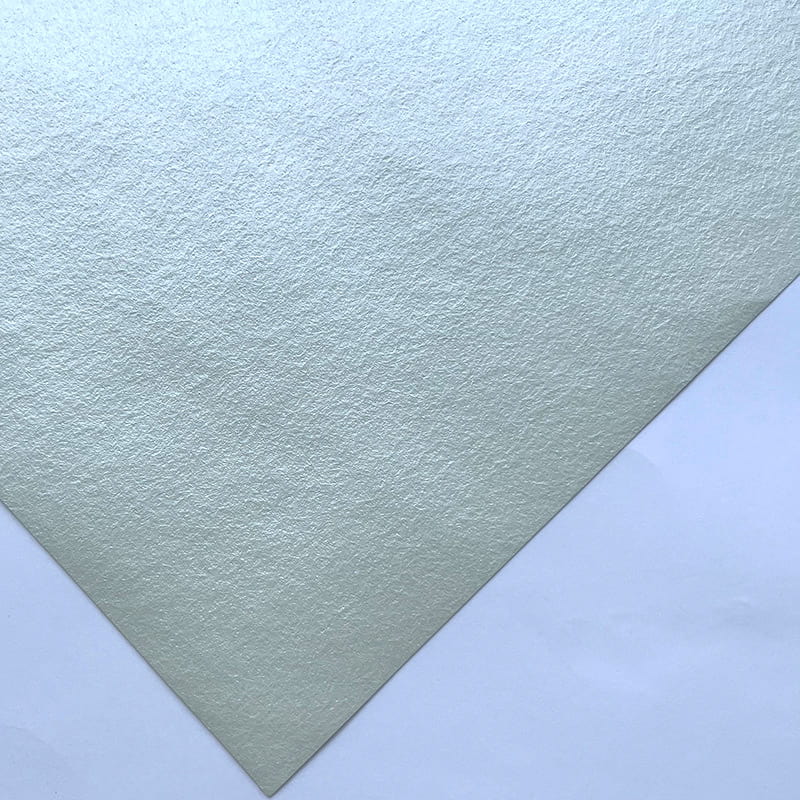

Material Characteristics of Vinyl Wallcovering

Vinyl wallcovering is primarily composed of a polyvinyl chloride (PVC) layer combined with a backing material, typically paper, fabric, or non-woven substrates. The surface can be embossed, printed, or coated with protective finishes to enhance aesthetics and performance.

Key performance attributes include:

- Durability: Resistance to abrasion and scratches makes it suitable for high-traffic areas.

- Moisture Resistance: Superior performance in humid conditions compared to paper-based coverings.

- Design Versatility: Compatibility with digital printing allows limitless design options.

- Ease of Maintenance: Washable surfaces simplify cleaning without compromising aesthetics.

These attributes make vinyl wallcovering a material of choice across multiple applications, from hospitality interiors to residential living spaces.

Industrial Production Process

The manufacturing of vinyl wallcovering involves a multi-stage process that integrates raw material preparation, surface treatment, and post-production finishing.

-

Raw Material Preparation

- Polyvinyl chloride resins are blended with stabilizers, plasticizers, and additives to achieve flexibility and durability.

- Substrate materials, such as non-woven fabrics, provide dimensional stability and allow easy installation.

-

Coating and Laminating

- The vinyl layer is coated onto the substrate through calendaring or extrusion.

- Laminating techniques ensure strong adhesion between vinyl and backing, preventing delamination.

-

Printing and Embossing

- Gravure and digital printing techniques enable detailed patterns, textures, and colors.

- Embossing rollers provide three-dimensional effects that enhance tactile quality.

-

Protective Finishing

- Surface coatings improve stain resistance, UV stability, and antimicrobial performance.

- Matte, satin, and glossy finishes meet diverse aesthetic preferences.

Digital Printing and Innovation in Vinyl Wallcovering

Recent developments emphasize the integration of digital printing technologies, which expand creative possibilities and improve production efficiency. Shanghai MIRO Import and Export Co., Ltd., adhering to the mission of “continuously researching and developing innovative digital printing materials”, plays a key role in promoting this trend. By adopting water-based inks and eco-friendly binders, manufacturers ensure high-resolution designs while aligning with sustainability goals.

Digital technologies also allow for shorter production runs and customized designs, supporting the growing demand for personalized interior solutions. This has opened opportunities for custom vinyl wallcovering manufacturers, factory operations, which specialize in tailored production for architects, designers, and project developers.

Environmental Considerations

The vinyl wallcovering industry has historically faced scrutiny due to environmental concerns associated with PVC. However, advancements in eco-friendly production methods have significantly reduced the environmental footprint.

- Use of Water-Based Inks: Replacing solvent-based systems with water-based inks reduces volatile organic compound (VOC) emissions.

- Formaldehyde-Free Adhesives: These ensure indoor air quality and compliance with international safety standards.

- Recyclable Materials: Substrates and coatings designed for recyclability contribute to circular economy practices.

- Energy-Efficient Manufacturing: Modern facilities adopt green production methods to minimize resource consumption.

Shanghai MIRO Import and Export Co., Ltd., as a domestic environmental decoration materials manufacturer, exemplifies this transition by focusing on sustainable wallpaper, wall coverings, and canvas, ensuring compliance with global eco-standards.

Market Applications

Vinyl wallcovering is widely applied across various market sectors due to its adaptability:

-

Residential Spaces

- Enhances aesthetic appeal in living rooms, bedrooms, and kitchens.

- Offers practical solutions for moisture-prone areas like bathrooms.

-

Commercial Interiors

- Preferred in hotels, restaurants, and retail environments for durability and design versatility.

- Provides brand-specific customization opportunities through digital printing.

-

Institutional Environments

- Common in healthcare, education, and office settings due to hygiene and performance requirements.

- Antimicrobial coatings support safety in sensitive spaces.

Industry Trends and Future Outlook

The vinyl wallcovering industry continues to evolve along three primary directions:

- Customization and Personalization: Growing demand for custom vinyl wallcovering manufacturers, factory services reflects the trend toward unique, project-specific solutions.

- Eco-Sustainability: Continuous innovation in recyclable materials and low-impact adhesives is reshaping the industry’s environmental profile.

- Integration with Smart Design: Digital printing and automated production processes enhance both efficiency and creative potential.

As international markets place greater emphasis on sustainable interior materials, enterprises that combine advanced production techniques with green initiatives will maintain competitive advantages.

Role of Shanghai MIRO Import and Export Co., Ltd.

As a comprehensive enterprise specializing in building decoration materials, Shanghai MIRO Import and Export Co., Ltd. integrates research, development, production, and sales under one system. With expertise in eco-friendly wallpaper, wall covering, and canvas, the company demonstrates the integration of innovation with environmental responsibility. Its focus on sustainable wallcoverings, recyclable substrates, and water-based printing technologies ensures products meet international standards while providing safe, stylish, and eco-conscious solutions for global customers.

Conclusion

Vinyl wallcovering remains a cornerstone of modern interior decoration, supported by its durability, versatility, and adaptability to both residential and commercial spaces. The industry’s future is shaped by digital printing technologies, environmental innovations, and the growing demand for customization. Enterprises such as Shanghai MIRO Import and Export Co., Ltd. exemplify this development by combining sustainable practices with advanced R&D capabilities.

The continuous evolution of vinyl wallcovering not only reflects broader design and sustainability trends but also positions it as a key material in the transformation of interior decoration, where functionality, aesthetics, and environmental responsibility must coexist harmoniously.

中文简体

中文简体 English

English русский

русский Español

Español عربى

عربى