The Path of Innovation for Non-Woven Wallpaper: Environment and Technology

As a comprehensive enterprise dedicated to eco-friendly building and decorative materials, our company exemplifies two core directions in the industry’s development: environmental innovation and technological advancement.

R&D and Application of Eco-Friendly Materials: Practicing Sustainability from the Source

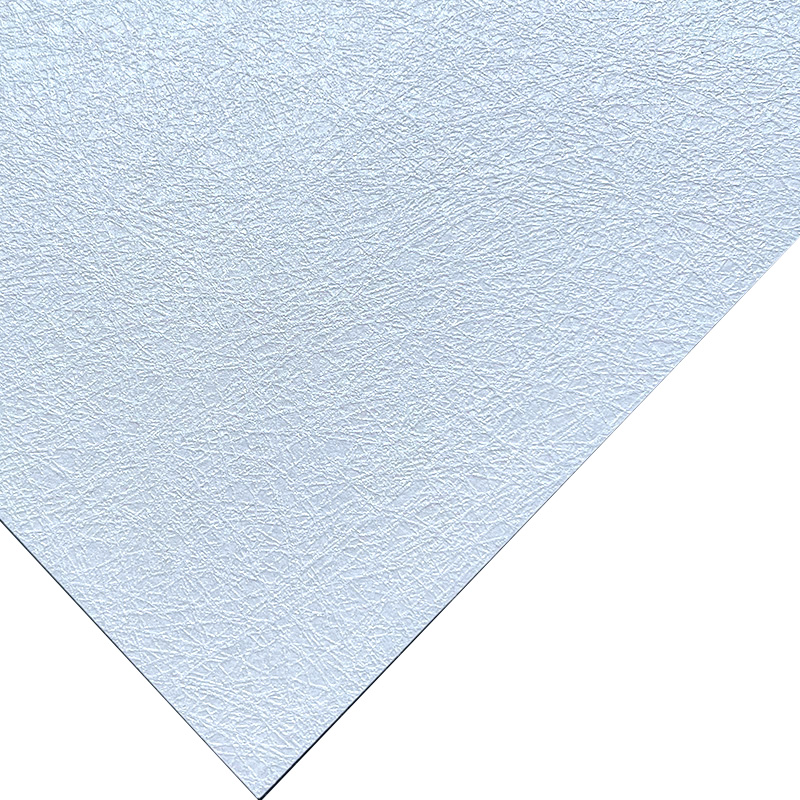

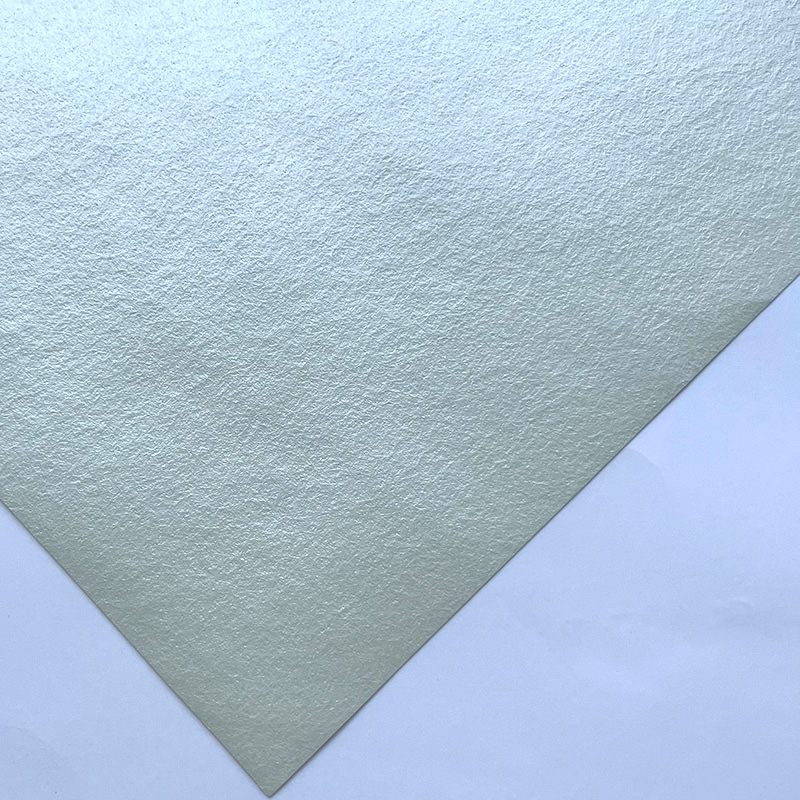

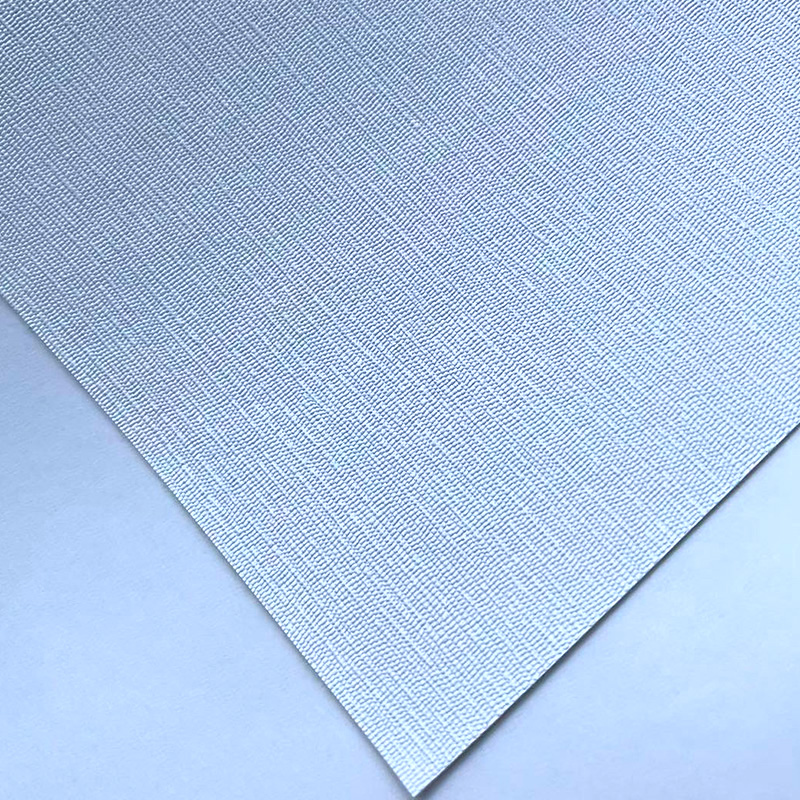

A central focus of our operations is the development and sales of sustainable materials, particularly latex-saturated non-woven wallcoverings. This reflects our commitment to environmental protection starting from the very source of production—the raw materials. While traditional wallpaper backings may contain chemicals harmful to health, non-woven substrates are made from plant or synthetic fibers that are breathable and eco-friendly. Through latex saturation technology, we enhance both the stability and durability of the non-woven base while ensuring products are free from formaldehyde and other volatile organic compounds (VOCs), meeting today’s stringent consumer demands for indoor air quality. This dedication to sustainable material innovation lies at the heart of our identity as a trusted manufacturer.

Advanced Technical Equipment: Ensuring Performance and Quality

Technological advancement is reflected not only in materials but also in production processes and equipment. Our Anhui production base features three advanced coating lines, two back-glue coating machines, and a range of embossing, calendering, and precision slitting inspection systems. These facilities ensure high efficiency and precision throughout the manufacturing process.

- Coating lines guarantee uniform surface application, improving wear resistance, water resistance, and color fastness.

- Back-glue coating machines simplify installation and reduce the need for additional adhesives, thereby minimizing potential chemical emissions.

- Embossing and calendering equipment produce diverse textures and three-dimensional effects, catering to personalized and custom market needs while enhancing artistic value.

- Inspection systems serve as the final quality gate, ensuring every roll meets rigorous standards before reaching the customer.

Through these technological investments, we enhance not only the environmental profile of our products but also their functionality, aesthetics, and usability. This dual commitment to material innovation and advanced manufacturing forms our competitive edge in the non-woven wallpaper sector.

How an Economical Factory Achieves Rapid Response for “Small Batch, Multi-Color” Orders

For a company with strong R&D, production, and export capabilities like ours, being “economical” does not mean compromising on quality. Instead, it reflects a strategic balance achieved through technological innovation, lean management, and scalable infrastructure. Here’s how we ensure rapid response to “small batch, multi-color” orders:

Hardware Foundation: Flexible Advanced Equipment as the Backbone

Our Anhui production base is equipped with three advanced coating lines and two back-glue coating machines, forming a robust foundation for agile manufacturing.

- Flexible Production: These production lines are highly adjustable. By swiftly changing molds and process parameters—such as coating volume, speed, and temperature—we can transition between producing non-woven substrates of varying weights and finishes within the same day. This allows rich material options for “multi-color” demands without major downtime.

- Precision Control: Advanced equipment ensures process stability and product consistency, essential for minimizing waste and defects even in small-batch production.

Core Technology: Digital Printing as the Engine

To achieve true “multi-color” flexibility and fast turnover, we employ digital inkjet printing technology.

- Zero-Cost Pattern Change: Digital printing uses digital artwork files without the need for physical plates, eliminating setup fees and delays. This makes small batches as economically viable as larger runs.

- Unlimited Design Potential: Whether intricate gradients, high-definition patterns, or fully customized graphics, digital printing delivers exceptional results, aligning perfectly with our R&D-driven approach.

Process Optimization: Lean Production as the Enabler

Advanced hardware alone isn’t enough—efficient processes are critical.

- Modular Workflows: We use a modular production approach where order information and material flow are synchronized, drastically reducing lead times from order receipt to production launch.

- Standardization and Databases: A well-defined color management system, material database, and process parameters allow quick matching and fine-tuning for new orders, avoiding time-consuming trial runs.

- Order Grouping: For very small orders, we apply a “group order” model—combining multiple small orders with different patterns on the same production run. This optimizes equipment use and reduces per-order cost.

Company Positioning: Integrated R&D and Sales as the Advantage

We operate as an integrated enterprise where R&D, production, and sales work in synergy.

- R&D Front-Loading: Our R&D team not only develops new materials and techniques but also maintains an extensive library of trending patterns. This allows quick customization and shortens design cycles.

- Sales-Production Integration: With a strong export orientation, our sales team understands international demand for agility. Streamlined workflows ensure smooth transitions from inquiry and design confirmation to sampling and production.

Conclusion

In summary, our business model leverages:

A large-scale facility (15,000㎡ park) and advanced equipment as the foundation;

Digital printing technology to overcome the cost challenges of multi-color production;

Lean and flexible processes to enable rapid turnaround;

And an integrated operational structure that combines R&D and sales.

Together, these elements allow us to respond with speed, quality, and cost-efficiency to “small batch, multi-color” orders—giving us not only a pricing advantage but also exceptional market agility.

中文简体

中文简体 English

English русский

русский Español

Español عربى

عربى