How Do Modern Wallpaper Factories Achieve Easier Pasting and More Eco-Friendly Performance? – The Case of Shanghai MIRO

The competition in the modern wallpaper manufacturing industry has gone far beyond the competition of pattern design; it is more deeply a contest of materials science and production technology behind the products. A convenient pasting experience and excellent environmental performance have become the core pursuits of leading manufacturers. Since its establishment in 2001, Shanghai MIRO Import & Export Co., Ltd. has always focused on the research, development, and production of building decoration materials. Its Anhui plant is a model for achieving this goal.

Easy Pasting: Empowering Technology to Simplify the Construction Process

The core of convenient pasting lies in the mature application of "pre-pasting technology," and MIRO's advanced equipment guarantees this.

1. Advanced Pre-paste Production Lines: The two specialized backglue coating machines equipped at the MIRO Anhui plant are key to achieving this goal. These machines can evenly and precisely apply an eco-friendly adhesive layer to the back of the wallpaper before it leaves the factory. Users only need to activate the back glue with water during installation to paste, completely eliminating the cumbersome process of manually mixing and applying glue traditionally. This avoids problems like bubbling and edge warping caused by uneven glue application, greatly simplifies the process, and reduces reliance on professional construction skills.

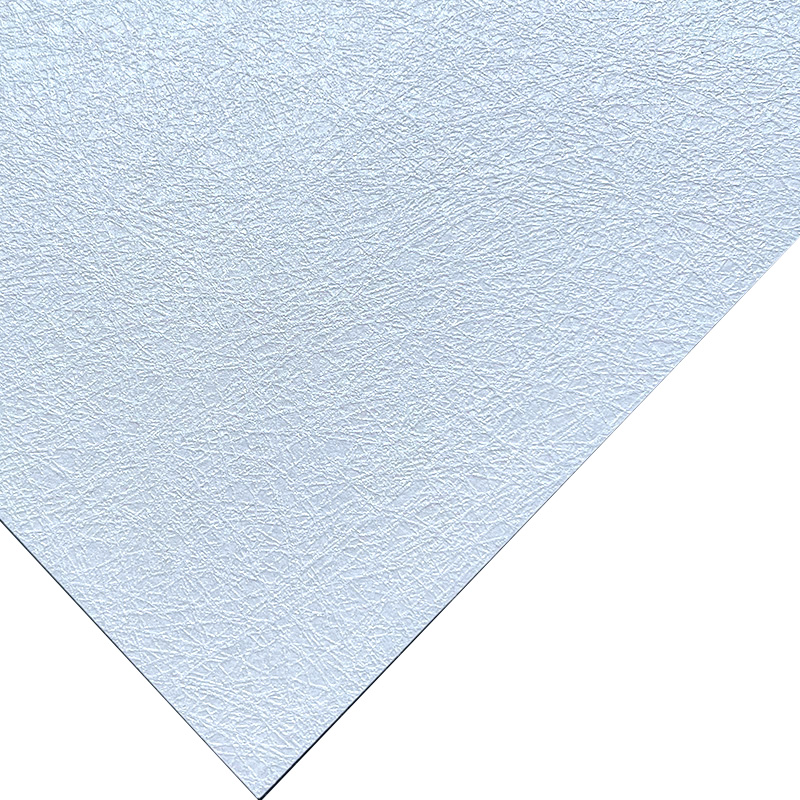

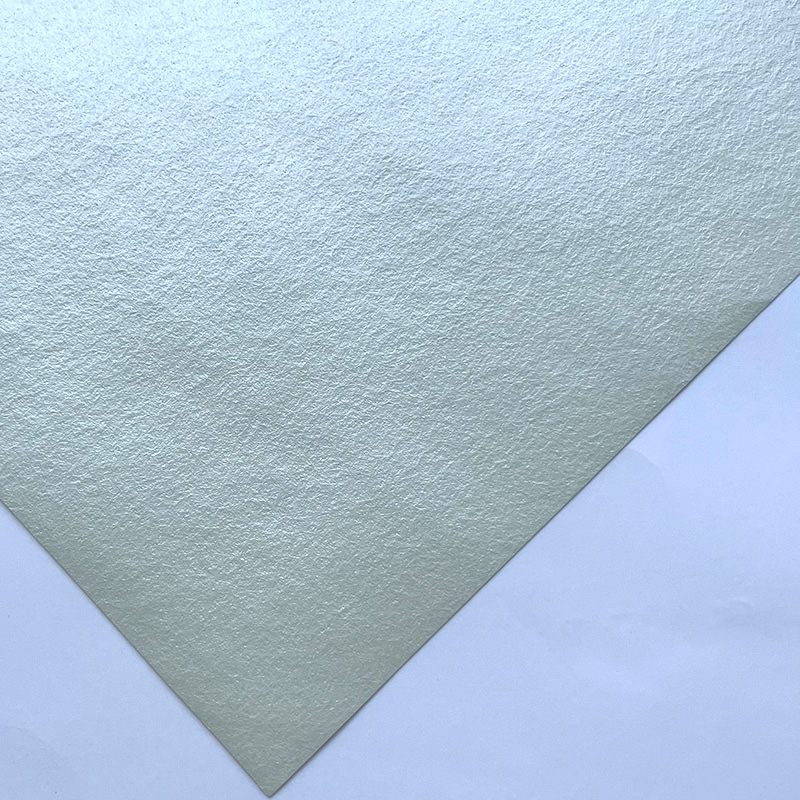

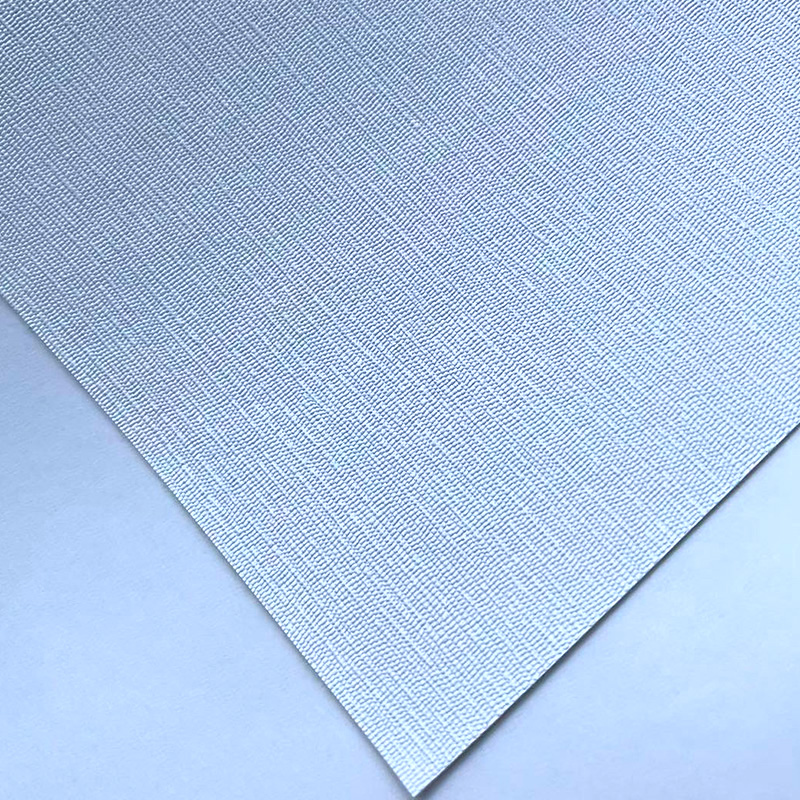

2. High-quality Base Material Selection: MIRO specializes in producing latex-saturated non-woven wallcovering. The non-woven base material itself has high dimensional stability and is flexible and resistant to pulling. Combined with pre-pasting technology, its "breathability" allows water to quickly and evenly penetrate and activate the adhesive layer, while the base material does not over-expand or shrink, making wall application smoother and allowing for minor position adjustments without easy damage, further enhancing the fault tolerance and convenience of pasting.

Environmental Performance: Full-chain Control from Source to Production

Environmental performance is the foundation of MIRO's status as "China custom eco-friendly sustainable wallpaper manufacturers." This is reflected at three levels: raw materials, production process, and final product.

1. Commitment to Eco-friendly Raw Materials: MIRO clearly places "eco-friendly materials" at the core of its products. This means its products largely use water-based inks for printing, preventing the volatilization of harmful substances from solvent-based inks; its non-woven base materials mostly come from natural wood pulp or environmentally friendly synthetic fibers; and the pre-applied adhesive layer must necessarily be low-VOC (Volatile Organic Compounds) or zero-VOC water-based eco-friendly glue, ensuring product safety and sustainability from the source.

2. Large-scale and Standardized Production Ensures Quality: The modern plant covering 15,000 square meters and the three advanced coating production lines ensure a stable and controllable production environment and process. Standardized, large-scale production avoids quality fluctuations and potential pollution that can occur in small workshops due to unstable processes. Equipment like embossing and calender machines enhances the product's texture without relying on harmful chemical additives to achieve visual effects.

3. Stringent Quality Control System: The mentioned scuttling inspection equipment is a key part of ensuring the final environmental performance. This equipment is used for continuous testing of the wallpaper's physical properties (such as scrub resistance and color fastness) and environmental indicators throughout the production process, ensuring that every roll of wallpaper leaving the factory meets strict international environmental standards (such as EU CE certification, REACH regulations, etc.), providing users with a truly safe, healthy, and odor-free indoor environment.

Conclusion

In summary, Shanghai MIRO Import & Export Co., Ltd., through its strong R&D capabilities, advanced hardware equipment (such as specialized backglue coating machines and non-woven production lines), and the consistent integration of environmental philosophy, successfully combines a convenient user experience with excellent environmental performance. Its factory is no longer a simple processing site but an innovation platform that deeply integrates technology, materials, and user-friendly needs. What is ultimately delivered to consumers is not just a beautiful roll of wallpaper, but a promise of immediate enjoyment and peace of mind for health and safety.

Flexible Production and Design Support: Shanghai MIRO's Core Competitiveness in the Customization Wave

In today's personalized consumption era, the demand for customization in the wallpaper industry continues to grow. Established in 2001, Shanghai MIRO Import & Export Co., Ltd. has consistently focused on the R&D and production of building decoration materials including eco-friendly materials and wallcoverings. By building a comprehensive flexible production system and design support infrastructure, the company maintains strong competitiveness amid the customization trend.

I. Building a Flexible Production System

Shanghai MIRO has established a complete flexible manufacturing system at its Anhui production base. Within the 15,000 square meter facility, the three advanced coating production lines and two backglue coating machines enable quick switching between different materials, specifications, and processes. This production line configuration allows the factory to handle both large-volume standardized orders and small-batch, multi-variety customized requirements.

The company's production equipment combination offers significant flexibility: embossing equipment can quickly change pattern rollers, calender machines can adjust processing effects, and scuttling inspection equipment ensures quality stability for each custom order. This equipment setup enables MIRO to achieve product diversification while maintaining production efficiency.

II. Comprehensive Design Support System

As a custom eco-friendly sustainable wallpaper manufacturer, Shanghai MIRO has established a complete design support service system. The company not only provides a rich selection of base materials, including various environmentally friendly non-woven wallpaper materials, but also offers professional design consultation and technical support services to customers.

The design team can quickly provide pattern design, color matching, and material selection recommendations based on customer requirements. Through digital design tools and sample production systems, customers can visualize effects before production, significantly improving the accuracy of custom solutions and customer satisfaction.

III. Collaborative Innovation Between R&D and Production

Among the company's 50 employees, R&D personnel and production technical staff maintain close collaboration. This organizational structure ensures seamless transition from design concept to finished product output. The R&D team continuously develops new environmentally friendly materials and production processes, while the production team quickly applies these innovations to actual production.

By continuously optimizing production processes, Shanghai MIRO can reduce the production cycle of custom orders to industry-leading levels while maintaining high standards in product quality and environmental performance. This rapid response capability allows the company to gain competitive advantage in the fierce market competition.

Conclusion

Shanghai MIRO has successfully transformed customization demands into development opportunities by building a flexible production system and comprehensive design support system. The company's 15,000 square meter production base and advanced equipment configuration provide solid assurance for meeting diverse market needs. In the customization wave, MIRO demonstrates a successful example of transformation and upgrading of traditional manufacturing enterprises, continuously providing global customers with high-quality eco-friendly wallpaper products through technological innovation and service improvement.

中文简体

中文简体 English

English русский

русский Español

Español عربى

عربى