Wallpaper, as an important element of interior decoration, has a procurement process that directly impacts the progress and quality of renovation projects. However, due to the diverse materials, numerous specifications, and high demands on packaging and storage conditions during transportation, procurement efficiency and reliability often face challenges. Therefore, optimizing logistics solutions can not only improve the efficiency of wallpaper procurement but also ensure the integrity and quality of the product during transportation and delivery.

I. Optimizing Warehouse Layout to Improve Logistics Response Speed

The efficiency of wallpaper procurement largely depends on the level of warehouse management. Traditional warehousing models often neglect the characteristics of wallpaper products, leading to excessive time spent on picking, sorting, and distribution. By scientifically planning the warehouse layout, the logistics response speed can be significantly improved. Classifying and storing warehouse areas according to the material, size, and popularity of the wallpaper helps to quickly locate the required products and reduce internal handling time. At the same time, using automated warehousing equipment, such as intelligent shelves and picking robots, can achieve fast and efficient sorting operations while ensuring product safety, thereby improving overall logistics efficiency.

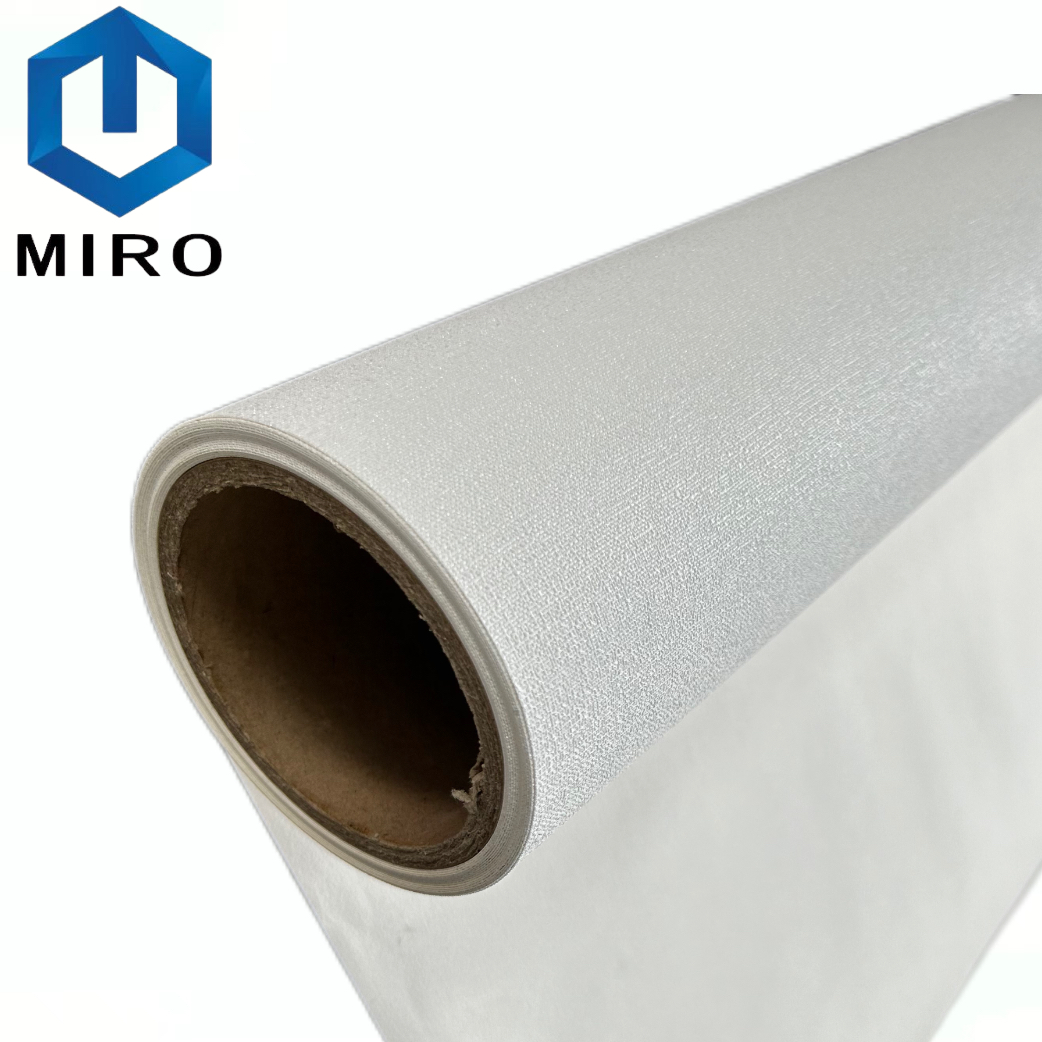

The rolled structure and easily deformable nature of wallpaper require a dry and constant temperature storage environment to prevent edge deformation and material dampness. Optimizing the warehouse layout not only focuses on space utilization but also needs to consider the stability of the product storage environment, which directly relates to the effectiveness of the wallpaper after delivery and customer satisfaction.

II. Refined Transportation Solutions to Ensure Product Integrity

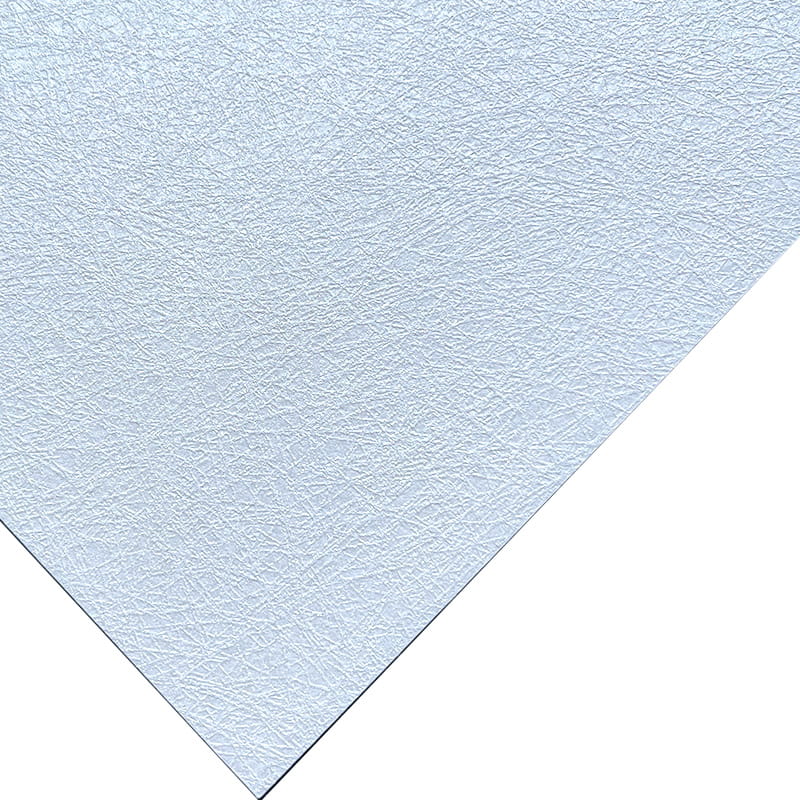

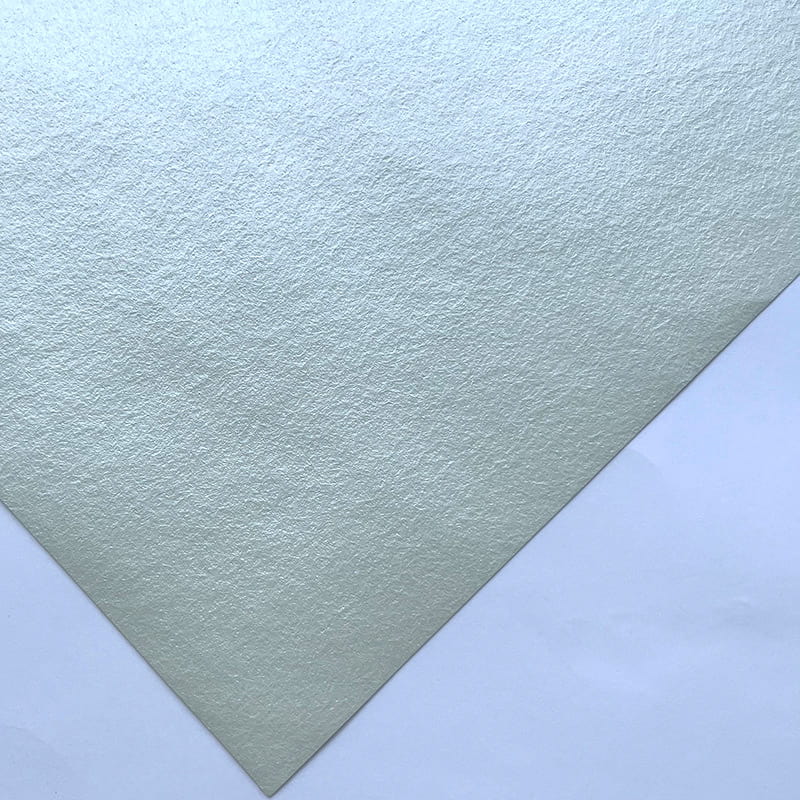

In wallpaper procurement, the transportation link is a crucial factor affecting reliability. Because wallpaper is easily damaged by compression, friction, and even humid environments during handling, the logistics solution needs to be meticulously designed in terms of transportation methods, packaging methods, and transportation routes. By selecting suitable transportation vehicles and implementing cushioning protection and moisture-proof measures during transportation, the damage rate of wallpaper during transportation can be effectively reduced.

Reasonable planning of transportation routes is also a key factor in improving efficiency. Based on the delivery frequency, quantity, and destination of wallpaper procurement orders, combined with traffic conditions and delivery time windows, designing scientific transportation routes can reduce intermediate stops and repeated transportation, thereby improving delivery speed and reliability. Real-time monitoring of the transportation process through a logistics information system can promptly detect transportation abnormalities and ensure that the wallpaper arrives at its destination on time and in good condition.

III. Information Management Enhances Procurement and Logistics Collaboration

Improving the efficiency of wallpaper procurement is inseparable from information management. By establishing a comprehensive logistics information system, real-time synchronization of purchase orders, inventory status, and transportation progress can be achieved, improving the coordination between logistics and procurement. Information management not only facilitates inventory alerts and order processing but also optimizes procurement plans through data analysis, reducing inventory backlog and stockout risks.

In the wallpaper procurement process, there are numerous products with different specifications, materials, and patterns. Relying on manual management can easily lead to errors and delays. An information system can achieve automated data entry, order allocation, and logistics scheduling, significantly improving the efficiency of procurement and logistics. Simultaneously, data sharing with suppliers and distributors ensures transparency of upstream and downstream information, helping to quickly respond to market demand changes and guarantee the continuity and reliability of wallpaper supply.

IV. Smart Packaging Solutions Reduce Logistics Losses

The fragile nature of wallpaper products makes packaging solutions a critical link in improving logistics reliability. Using packaging materials that match the characteristics of the wallpaper material can effectively reduce losses during transportation and handling. For example, moisture-proof, pressure-resistant, and shock-proof packaging designs can protect the shape and surface quality of wallpaper rolls, preventing warping, damage, or stains. Smart packaging solutions can also combine technologies such as barcodes and RFID to achieve traceable product management, improving the accuracy and transparency of logistics operations.

In the procurement process, suppliers can customize packaging solutions based on order volume and product specifications, enabling on-demand packaging and rapid sorting, thereby improving overall logistics efficiency. Intelligent packaging not only guarantees the quality of wallpaper products but also reduces transportation costs to a certain extent, improving the reliability and cost-effectiveness of the procurement process.

V. Flexible Distribution Models for Efficient Supply Chain Collaboration

Flexible distribution models are an important guarantee for the efficiency and reliability of wallpaper procurement. Based on procurement needs, multi-level and multi-modal distribution solutions can be adopted, including direct delivery, centralized distribution, and cross-regional distribution. Flexible distribution models can be optimized based on order volume, delivery time, and logistics capabilities to achieve efficient衔接 between inventory and transportation.

In supply chain collaboration, logistics solutions should fully consider the needs of wallpaper suppliers, warehousing centers, and end customers. Through reasonable distribution strategies and time management, rapid delivery and maximization of order fulfillment rates can be achieved. The flexible distribution model not only improves the responsiveness of the procurement process but also enhances the resilience of the supply chain, enabling it to cope with unexpected demands and transportation fluctuations.

FAQ

Q1: What are the most common quality problems in wallpaper logistics?

During transportation and storage, wallpaper is prone to problems such as curling edges, surface abrasion, moisture damage, and packaging damage. Proper warehouse management, transportation protection, and intelligent packaging solutions can effectively reduce these risks.

Q2: What specific roles does information management play in wallpaper procurement?

Information management enables inventory monitoring, order tracking, transportation scheduling, and data analysis, thereby optimizing procurement plans, improving logistics response speed, and reducing the risk of stockouts or excess inventory.

Q3: How to improve the timeliness of wallpaper procurement?

By optimizing warehouse layout, refining transportation, using intelligent packaging, and implementing flexible distribution models, it is possible to achieve fast picking, stable transportation, and efficient delivery, thus significantly improving the timeliness of procurement.

Q4: What are the environmental requirements for wallpaper transportation?

During wallpaper transportation, it is important to avoid humid, high-temperature, and compressive environments, maintaining constant temperature and dry conditions to ensure the integrity of the product surface and rolls, preventing damage and deformation.

中文简体

中文简体 English

English русский

русский Español

Español عربى

عربى