With the rapid development of digital and rotary screen printing technologies, wallcoverings are no longer limited to standard designs and repeat patterns. Today, printable wallcovering substrates play a crucial role in determining print quality, durability, and overall project performance. Among the most commonly used printable materials are nonwoven, PVC (vinyl), and textile-backed wallcoverings.

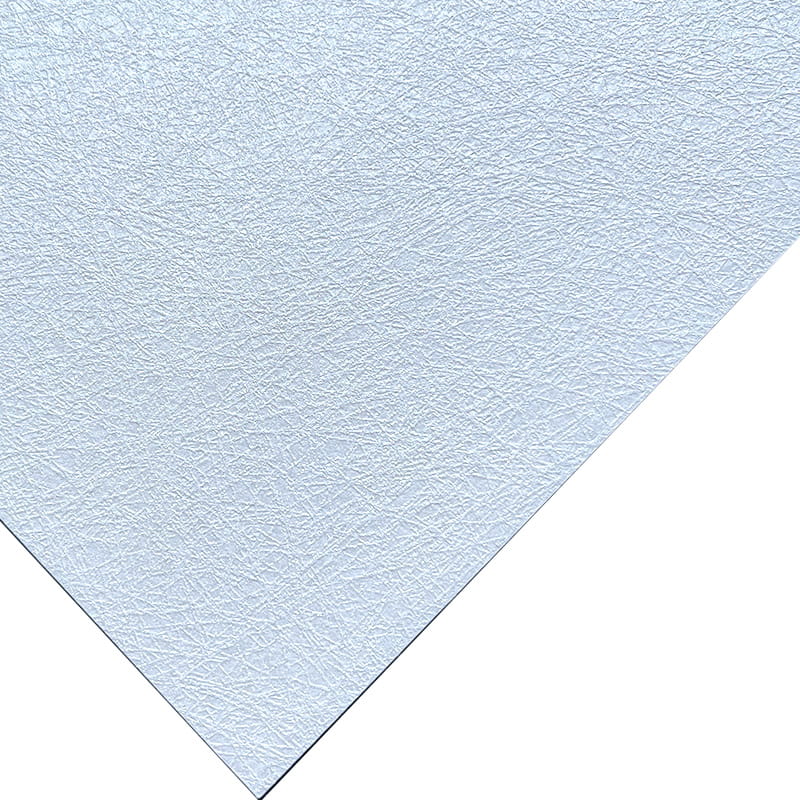

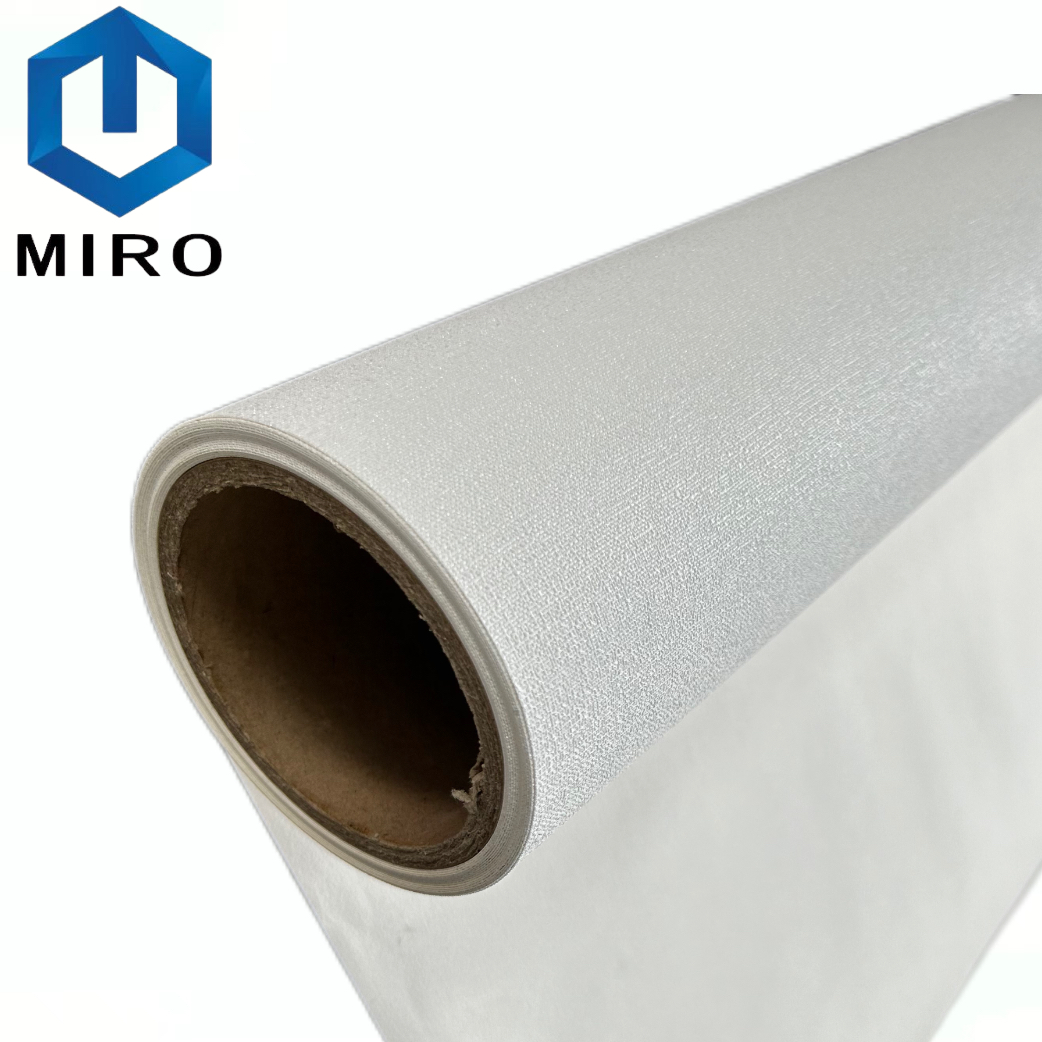

Printable nonwoven wallcoverings are widely adopted in digital printing due to their balanced performance and process stability. Made from a blend of cellulose and synthetic fibers, nonwoven substrates offer excellent dimensional stability, which is critical for large-format digital murals. They absorb inks evenly, resulting in consistent color reproduction and fine detail rendering, especially with latex and UV printing systems. From an application perspective, nonwoven materials are breathable and easy to install using paste-the-wall methods, making them suitable for both residential and commercial projects. Their main limitation is surface hardness, which can be improved through specialized coatings for contract-grade use.

Printable PVC (vinyl) wallcoverings are typically used in environments where durability and cleanability are key requirements. The vinyl surface provides high ink adhesion and strong color saturation, making it well suited for bold graphics and high-contrast designs. PVC substrates perform particularly well in hospitality, healthcare, and retail interiors where frequent cleaning is required. However, vinyl materials are less breathable and generally heavier, which can increase installation complexity. Environmental considerations are also an important factor when specifying PVC-based printable wallcoverings.

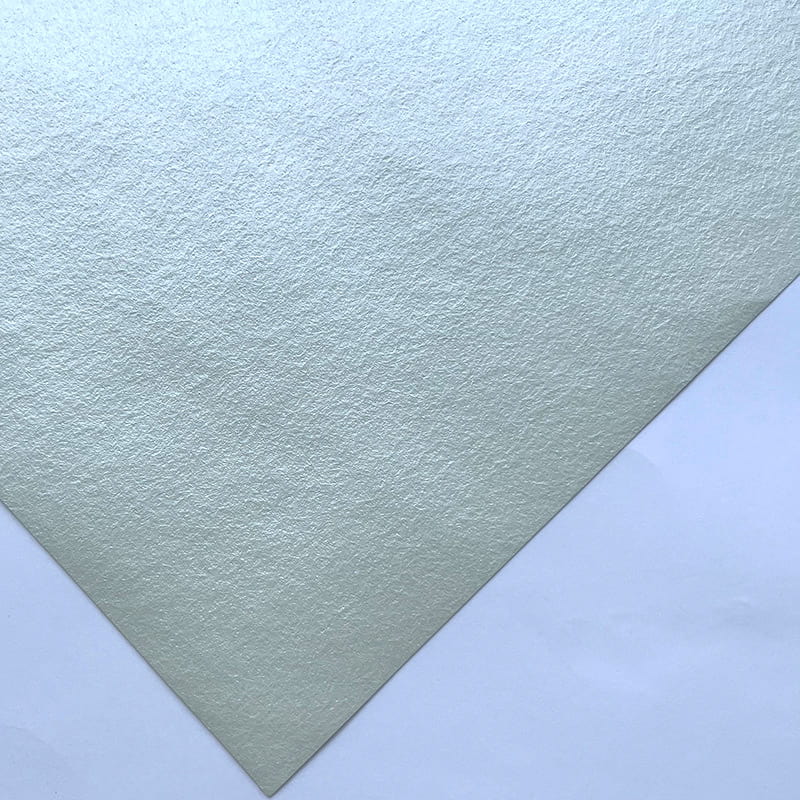

Textile-backed and textile-surface wallcoverings represent the premium segment of printable substrates. These materials provide a unique tactile and visual depth that cannot be achieved with smooth surfaces. When properly prepared for printing, textile substrates can deliver soft color transitions and a sophisticated, fabric-like appearance. However, printing consistency can be more challenging due to the structure of the fabric, and careful ink and process selection is required. In addition, textile wallcoverings often involve higher costs and more complex installation.

In conclusion, selecting the right printable wallcovering substrate depends on the intended printing technology, performance requirements, and end-use environment. Understanding how different materials interact with digital and screen printing processes enables printers and brands to achieve optimal visual results while meeting technical and regulatory demands.

中文简体

中文简体 English

English русский

русский Español

Español عربى

عربى