Why Is Bamboo Joint Fabric Gaining Increasing Attention in Modern Building and Interior Decoration?

With the growing emphasis on sustainability and eco-friendly practices, the selection of building and interior decoration materials is increasingly shifting toward environmentally responsible, high-performance, and aesthetically pleasing options. In this context, bamboo joint fabric has emerged as a key material in architecture and interior design due to its unique properties, sustainability, and decorative potential. As a new type of eco-friendly textile material, it not only meets contemporary design aesthetics but also offers durability and functional advantages, allowing designers and consumers to achieve personalized décor while maintaining environmental responsibility.

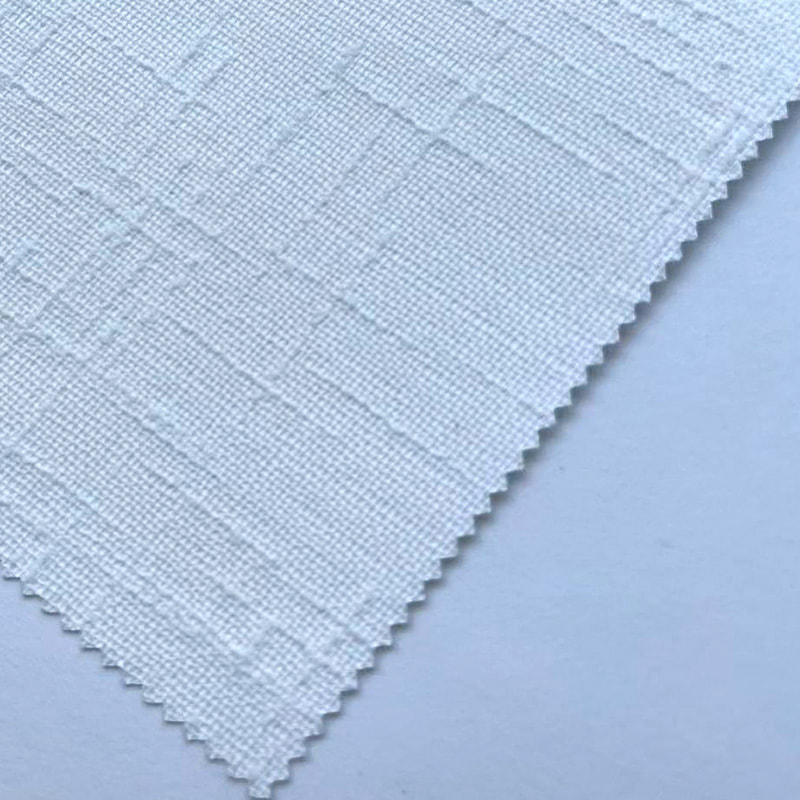

Material Characteristics of Bamboo Joint Fabric

Bamboo joint fabric is a composite material primarily made from bamboo fibers, combined through specialized joining techniques. Its key characteristics include:

- Natural and Eco-Friendly: Bamboo fibers are renewable, biodegradable, and have a short growth cycle, minimizing environmental impact.

- High Durability: Precision joining techniques enhance the fabric’s tensile strength, wear resistance, and tear resistance.

- Comfort and Breathability: Bamboo fibers naturally absorb moisture and allow airflow, making them ideal for wall coverings and interior textiles.

- Anti-Microbial Properties: Bamboo fibers have inherent antibacterial qualities, which, when combined with eco-friendly coatings or dyes, help prevent mold and bacterial growth.

These features make bamboo joint fabric suitable not only for interior wall coverings but also for functional textile applications, including eco-friendly canvas, partitions, and furniture upholstery.

Production Process and Technological Innovation

Producing high-quality bamboo joint fabric requires precise manufacturing processes and strict quality control. Key steps include:

- Raw Material Selection: Choosing premium bamboo fibers ensures uniform length, high strength, and minimal impurities.

- Weaving and Joining: Advanced joining techniques combine bamboo fibers with other natural or recycled fibers to form structurally stable and visually appealing composite fabrics.

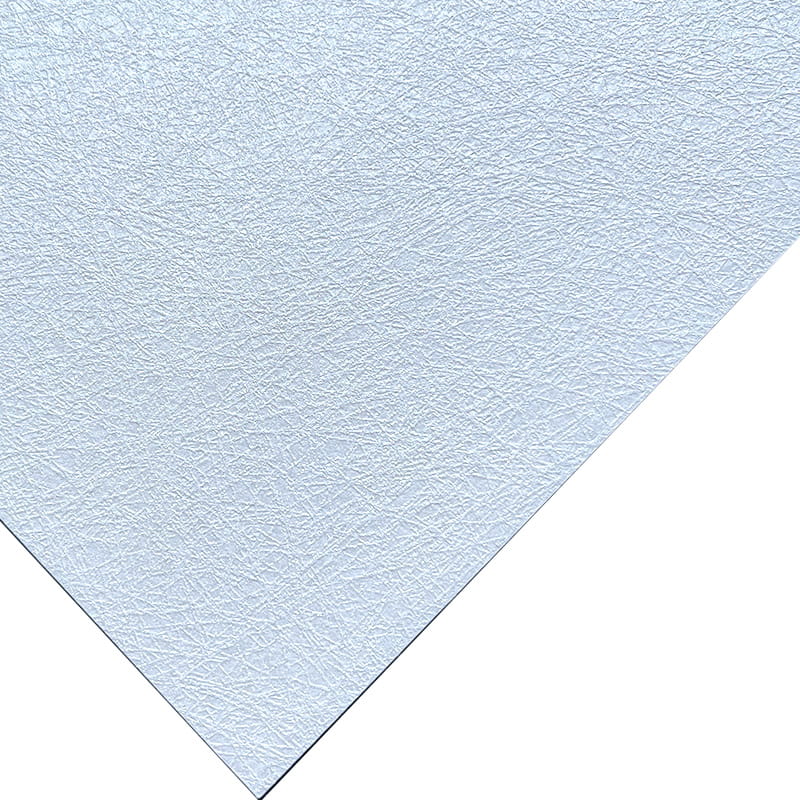

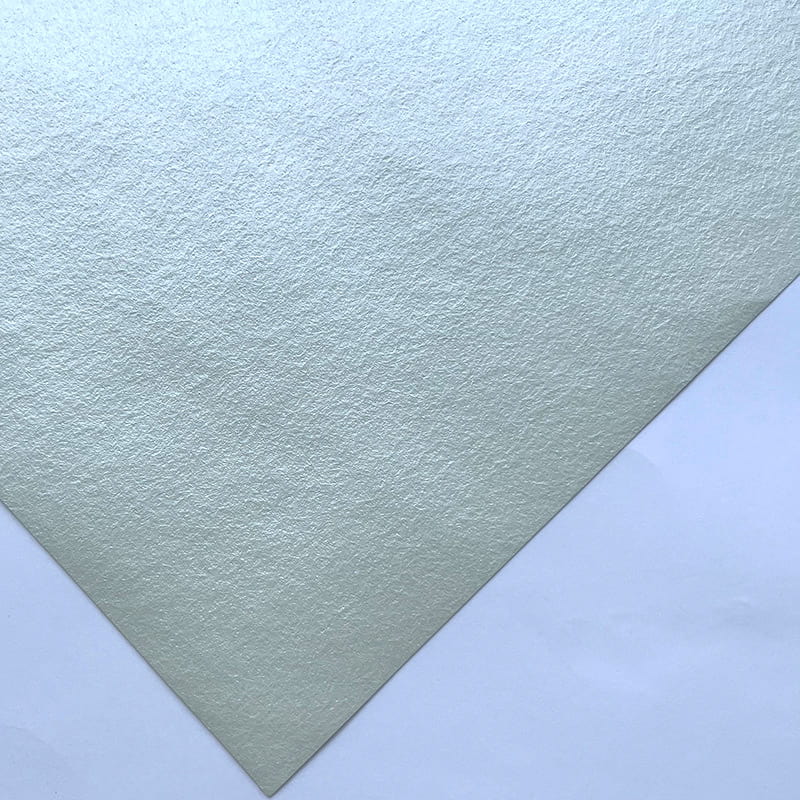

- Eco-Friendly Dyeing and Coating: Water-based inks and formaldehyde-free adhesives are used to achieve vivid colors while meeting international environmental standards.

- Post-Treatment and Inspection: Fire resistance, mold prevention, and wear-resistance treatments enhance functionality, followed by rigorous quality inspections.

Shanghai MIRO Import and Export Co., Ltd., a leading domestic manufacturer of eco-friendly building materials, focuses on digital printing materials and customized solutions. Their R&D team continuously optimizes bamboo fiber joining techniques, ensuring that bamboo joint fabric achieves industry-leading durability, aesthetics, and environmental performance.

Applications and Market Potential

The applications of bamboo joint fabric in architecture and interior design are extensive, including:

- Wall Coverings: Serves as an eco-friendly alternative to traditional wallpaper, providing natural textures and aesthetic appeal.

- Interior Soft Furnishings: Used for curtains, partitions, and furniture upholstery, combining beauty with functionality.

- Public Spaces: Ideal for hotels, offices, and commercial environments, enhancing space quality while meeting environmental standards.

- Customized Solutions: Collaborating with custom bamboo joint fabric manufacturers, factory, designers can create tailored colors, textures, and thicknesses to meet specific design requirements.

Market trends indicate steady growth in demand for bamboo joint fabric, driven by the rise of green buildings and eco-conscious interior standards. Its combination of environmental friendliness and premium aesthetics positions it strongly in mid-to-high-end interior decoration markets.

Environmental and Sustainability Advantages

Environmental performance is a major selling point of bamboo joint fabric. Compared to conventional synthetic fibers, it offers:

- Renewable Resources: Bamboo grows quickly and can be harvested multiple times annually, reducing resource consumption.

- Low-Carbon Production: Green manufacturing processes and energy-saving technologies reduce emissions and align with carbon reduction goals.

- Non-Toxic and Safe: Use of water-based inks and formaldehyde-free adhesives ensures safety for humans, suitable for both residential and commercial spaces.

- Recyclability: Incorporation of recyclable materials in the composite fabric reduces waste and supports circular material usage.

Shanghai MIRO Import and Export Co., Ltd. implements strict production controls and innovative processes in this field, continuously advancing the green development of bamboo joint fabric, providing clients with safe, stylish, and eco-friendly decorative solutions.

中文简体

中文简体 English

English русский

русский Español

Español عربى

عربى